一、开料

First, open material

开料同柜身板一样,就是门板的质地材料更多样化,对板材进行切割,高端用开料据或激光切割机,低端用手工推台锯,一体加工中心设备有的也带开料据。

Is expected to open with the cabinet body, door material is more diverse, on the plate cutting, cutting with high-end or low-end according to the laser cutting machine, hand push table saw, integrated processing center equipment with some materials according to.

二、开槽

Two, slotting

开槽的主要目的是安装拉手,开槽不能将门板的宽度开完,要留一点封口,否则拉手要从另一面抽出来了。开槽的厚度要和拉手的型号一致,要略小于拉手的插入厚度。雕刻机、推台锯、开料锯都可以进行开槽。

The main purpose of slotting is to install the handle, the slot can not open the width of the door plate, want to leave a little seal, otherwise the handle should be pulled out from the other side. Slotted thickness and handle the same model, slightly less than the thickness of the insertion handle. Engraving machine, push table saw, open saw can be slotted.

三、封边

Three, edge banding

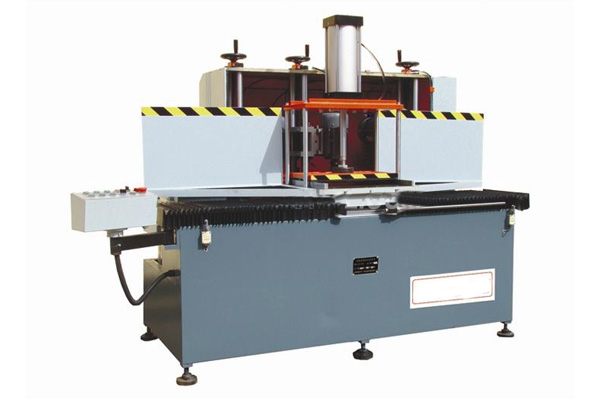

不同的材质决定是否需要封边,常见的封边材质有三聚氰胺、防火板、水晶板等。封边一般为门板的同色,一般为2mm的厚度,产品可以使用铝封边。机器用自动封边机、轻型封边机等都可以。

Different materials determine whether it needs edge banding. The common edge materials are melamine, fireproof board, crystal board and so on. The edge is generally the same color as the door panels, generally 2mm thickness, high-end products can use aluminum edge. Automatic edge banding machine, light edge banding machine and so on.

四、打孔

Four, punching

此处的打孔为门铰孔,移门软包产品可以是2-3个铰链,移门软包可以3-4个铰链,上下边距铰中心120为优。

Here is the door hinge hole drilling, the product can be a 2-3 soft door hinge, door hinge on a soft 3-4, below from the hinge center 120 is excellent.

五、锣槽(雕刻)

Five, Gong groove (carving)

锣槽就是在门板上进行雕刻花纹,可以说是凸显档次和产品销量的关键步骤,设备对步骤的影响比较大,普通木工雕刻机可以进行简单的线条雕刻,但是复杂的图形需要用到2把以上的刻刀,那么普通木工雕刻机就无能为力,这时可以选择多工序木工雕刻机或者一步到位直接选择上木工加工中心。多工序雕刻机可以自动换刀比人工换刀雕刻的精度要高,速度也更快,适合5把刀以下的雕刻图形,如果需要5把以上的图形雕刻那么是选择木工加工中心,标配刀库是8把,省心省力,适合任何高级图形的雕刻。

Gong groove is carved on the door, can be said to be a key step to highlight the quality and product sales, equipment on the steps of the impact is relatively large, the general woodworking engraving machine can be a simple line carving, but complex graphics need to use more than 2 of the knife, the general woodworking engraving machine is incapable of action, then you can selection of multi process woodworking engraving machine or one step direct selection of wood processing center. Multi process engraving machine can automatically change the knife to be higher than for artificial carving knife precision, speed is also faster, for the following 5 knife engraving graphics, if you need more than 5 graphics so it is best to choose the carved wood processing center, the standard knife is 8, worry and effort, for any advanced graphics carving.

六、吸塑

Six, blister

首先对门板进行打磨,然后喷胶,再将门板放入吸塑机即可,所用机器决定工艺品质,设备是真空吸塑机。

The door for grinding, and then glue, then the door into the plastic machine, the machine process quality, equipment is vacuum machine.

七、烤漆

Seven, baking paint

主要有人工完成,工艺比较复杂,建议找熟练的有经验技术的工人完成,主要步骤是:打磨——给铰边、封边处上密封底漆——进行双面人工打磨——晾干——再打磨——喷面漆——烤房烘烤——气劲打磨(除尘、凭证)——水磨——抛光——单面去纸等步骤。主要设备有磨枪、磨机等手工设备。

The main manual work, the process is complex, suggests looking for experienced skilled technology workers to complete, the main steps are: - to the hinge side edge grinding on sealing primer - Double - dry - grinding manual polishing, spray paint, curing barn - Jin (dust, gas proof) - grinding mill - - one side paper polishing steps. The main equipments are guns, mill and other equipment manual.

本文来自:

移门生产设备更多的精彩内容请点击我们的官方网站:

http://www.szwmdjx.com我们会有专门的客服为您解答。

This article from the production equipment: the more exciting content please click on our official website: http://www.szwmdjx.com we will have a special service for you to answer.